Samplify™ Automated Sampling System

- Description

- Purchase

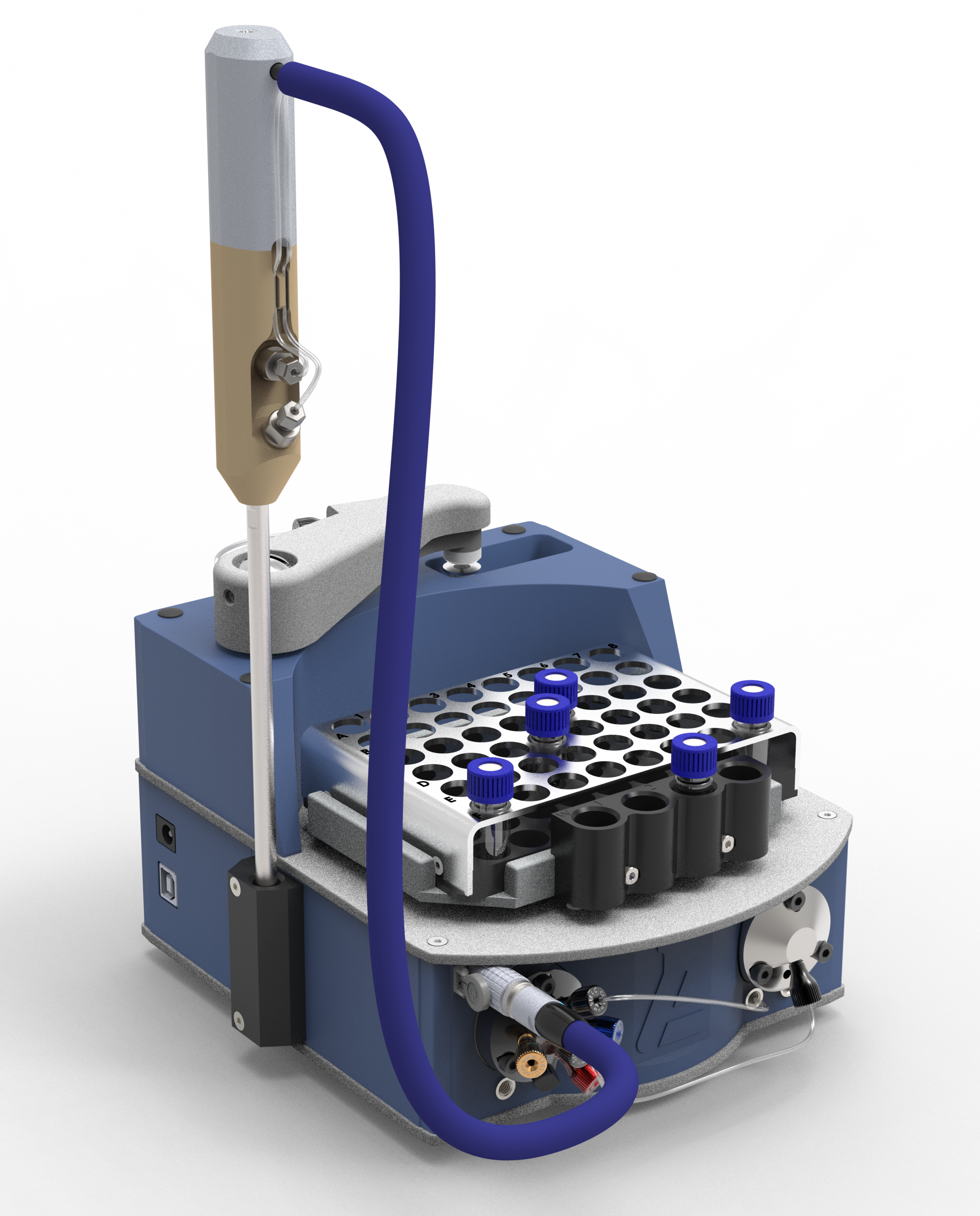

The Samplify™ Automated Sampling System

The Samplify™ Automated Sampling System performs sampling from any closed or open liquid-containing system, including Reactor setups with high pressure, high temperatures, or other extreme and hazardous conditions, without the need for operator intervention. It automatically collects samples at specified time intervals, improving accuracy, safety, and time efficiency. The Samplify™ reduces cross-contamination, prevents exposure to oxygen or moisture in anaerobic conditions, and enhances reproducibility.

System Components:

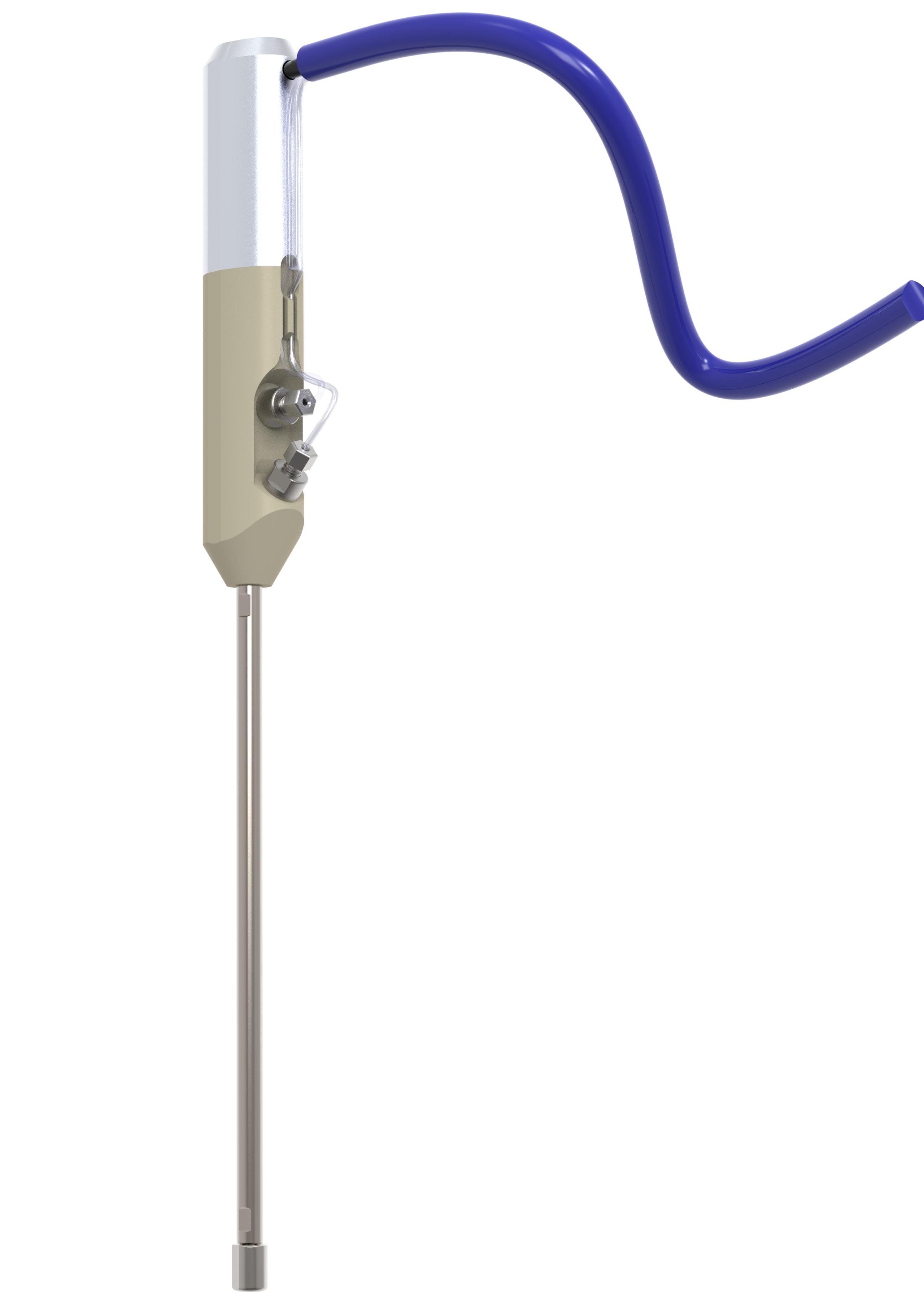

- Samplify™ Probe – an electromechanical device for precise, automated liquid sampling from closed or open systems, including Reactors. Made from reactive chemical-resistant materials, it ensures accurate, contamination-free sampling, even in high-temperature chemical solutions.

- Alltesta™ Mini Liquid Handling Station (LHS) – automatically extracts and distributes samples to designated locations.

Together, the Samplify™ Probe and Alltesta™ Mini LHS provide cost-effective and reliable automation for analytical and liquid-handling applications. The system enables precise sample collection, controlled dilution, and automatic quenching to preserve sample integrity. A shaking function ensures thorough mixing, while PC-based software allows quick and flexible experiment setup.

The compact design enables placement near Reactors with short connection lines to minimize dispersion. For temperature-sensitive samples, the system can operate in a controlled environment, with an optional cooler to maintain low temperatures after collection.

For pricing information, please contact us at alltesta@sielc.com.

Special Features:

- Standard vials: Universal collection vials ensure compatibility with HPLC and GC.

- Variable sample volume: A unique design allows users to select the sample volume to be collected.

- Variable dilution ratio: Desired dilution ratios can be easily achieved with a solvent.

- Automatic mixing: Automated vial shaking for fast mixing of samples with reagents.

- Compact Probe: Probe can be placed with the smallest vessel into a refrigerator.

- Up to 96 vessels: Can accommodate 48 and 96 samples at one time.

- Remote control: All processes may be controlled and monitored remotely.

- OEM and API: Interfacing available through API or OEM software.

- Minimal Dispersion: The compact device size enables close positioning to Reactors, reducing connection line length and preventing sample loss.

- Features from SIELC Technologies:

- The Samplify™ Automated Sampling System is controlled by a set of serial commands. An open comprehensive protocol is provided for customers who want to develop their own control software.

- The design is flexible – a variety of hardware options (valves, trays, syringes, needles, vials) and full software control over all modules. Full software integration support is provided for qualified customers.

Samplify™ Automated Sampling System

Performance Specifications of Samplify™ Automated Sampling System

| Samplify™ Automated Sampling Standard configuration | Samplify™ Automated Sampling Customizable configuration |

|

| Dimensions (WHL) | 160 x 145 x 195 mm / 6.3 x 5.71 x 7.68 in | depends on configuration |

| Weight | 3 kg / 6.6 lb | depends on configuration |

| Syringe Capacity | 4000 µL low-pressure stainless | 4000 µL low-pressure stainless 4000 µL low-pressure metal free |

| Plate | 48 vials | 48 vials 96-well plate |

| Pressure | Up to 250 psi | Up to 250 psi |

| Valve configuration | 7x6 | 7×6 |

| Power Requirements | 24 V | 24 V |

| Current Requirements | Up to 1.0 A | Up to 1.0 A |

| Inlets/Outlets | Thread 10-32 UNF compression type | Thread 10-32 UNF compression type |

| Materials in contact with liquid | SS316, PTFE, PEEK | SS316, PTFE, PEEK |

| Communication | RS232 Virtual COM port via USB | RS232 Virtual COM port via USB |

Performance Specifications of Samplify™ Probe

| Connection | Optionable |

| Dimensions | 1 x 1 inch, DIA ¼ inch. Immersion length up to 6 inch |

| Materials in contact with liquid | SS316, PTFE, PEEK |

| Variable sample volume | From 5 to 500 µL |

| Max. working pressure | 120 psi (8 bar) |

| Max. working temperature | 200 °C |

Applications of Samplify™ Automated Sampling System

- Chemical and Pharmaceutical Research: Continuous monitoring of chemical reactions and Reactor-based fermentation processes.

- Biotechnology & Bioprocessing: Automated sampling for cell culture and microbial Reactor studies.

- Environmental Analysis: Sampling of water and soil extracts for contaminant monitoring.

- Food & Beverage Industry: Quality control and ingredient verification.

Documents & Brochures

If you want more information, click here.

- Download the Samplify™ Automated Sampling System brochure here

- Download Samplify™ Probe Brochure here

If you need a user manual, please request it at alltesta@sielc.com

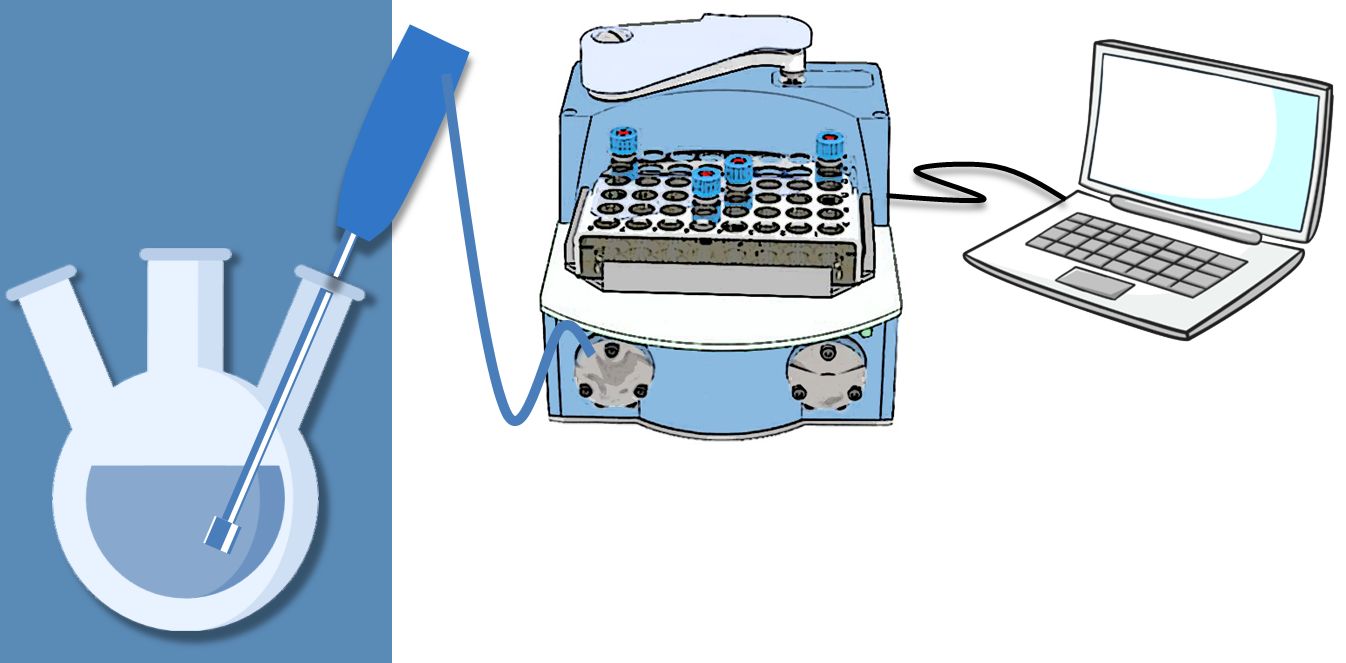

Software & Connectivity

The Samplify™ Automated Sampling System can be controlled through multiple interfaces:

- Direct Serial Commands: Via user software (Alltesta™ protocol available upon request at support@sielc.com)

- Cloud-Based Software: Remote access through autosampler.cloud

- PC Software Interface: Enables full control of sampling operations and parameters.

Contact us: For pricing or integration support, reach out at alltesta@sielc.com.

Samplify™ Is a device which allows unattended sampling of a reaction mixture or bioprocess or continue in line flow by taking small amount of liquid from the monitoring mixture and collecting it in a vial or a 96 wells plate. It also allows to dilute the sample with assigned dilution ratio and can provide reaction quenching to preserve the sample state at time of sampling. It has two main components: an autosampler and a probe. The Samplify™ controlled and setup by a PC software.

For pricing information, please contact us at alltesta@sielc.com.

36-month financing with market rates is offered to companies, individuals, and educational institutions subject to credit approval. For more details please contact us at financing@sielc.com.